+86-15829664021

liangma0318@gmail.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-03 Origin: Site

You use modern coal-mining methods to get coal in safer ways. These methods include surface mining and underground mining. Today, technology is very important in mining. Machines and automated systems help keep workers safe. They also help workers do more work faster. In the last ten years, technology has made safety rules better. It has also helped get better results. But worker safety still needs both machines and people. Modern coal-mining methods keep changing. Safety is always the most important thing in every part.

Modern coal mining uses surface and underground ways to get coal. These ways help keep workers safe and work faster. Technology is very important for safety and getting more work done. Smart machines and real-time monitoring systems help a lot. Surface mining is usually safer than underground mining. It lowers dangers like cave-ins and gas leaks. Protecting the environment is very important. New technology helps recycle water and fix land after mining. Companies like CCTEG are leaders in new mining ideas. They work on making mining better for the planet and less harmful.

There are two main ways to mine coal. These are surface mining and underground mining. Workers use these methods to get coal from the ground. Coal mining has changed a lot over the years. Today, technology helps people work safer and faster. New equipment and smart systems make each step better.

CCTEG Xi'an Research Institute is a leader in coal mining technology. They focus on making mining safer and more efficient. Their smart equipment and new technology help lower risks and get better results.

Surface mining lets workers reach coal close to the ground. The process removes soil and rock above the coal. Here is a table that shows the main types and how they have changed:

Mining Method | Description | Evolution in 2025 |

|---|---|---|

Surface Mining | Used when coal seams are near the surface, known for lower costs and efficiency. | Increased focus on sustainability and efficiency, with innovations in extraction techniques. |

Many types of equipment are used in surface mining:

Blasthole drills make holes for explosives.

Highwall miners take coal from exposed seams.

Draglines move lots of dirt.

Dozers clear land and remove soil.

Mining trucks carry coal and other things.

Drones help check and watch the site.

The main surface mining methods are:

Open-pit mining

Strip mining

Auger mining

Mountaintop removal

The method depends on where the coal seam is and how deep it is.

Underground mining helps workers reach coal deep underground. Shafts and slopes are used to get to these seams. Modern underground mining uses advanced equipment and technology. Real-time monitoring and smart systems keep workers safe.

Mining Method | Description | Evolution in 2025 |

|---|---|---|

Underground Mining | Employed for deeper seams, utilizing advanced safety and monitoring systems. | Integration of IoT and AI for real-time monitoring and enhanced worker safety. |

CCTEG Xi'an Research Institute gives tools like AI, geological modeling, and gas control systems. Workers use smart mine maps and teamwork to make mining safer. They also use clear geology and water hazard control to manage risks.

Now, coal mining depends on technology and smart equipment. These methods help people work safely and get more done.

Surface mining helps people get coal near the ground. Each step uses different coal mining equipment. The surface mining process has several main steps:

First, workers explore and plan. They use drills and survey tools to find coal.

Next, they clear the land. Bulldozers and excavators remove soil and rocks.

Then, workers take out the coal. They use draglines, trucks, and loaders.

After that, they process and move the coal. Waste is separated from coal and sent where it is needed.

Last, workers fix the land. They put back soil and plant trees to help nature recover.

Open-pit mining is a common way to mine coal. Workers dig a big pit to reach the coal seam. They use large coal mining equipment like shovels, haul trucks, and drills. Open-pit mining costs less and is safer. The pit can get bigger, and big machines help workers do more.

Aspect | Open-Pit Mining | Other Surface Mining Methods |

|---|---|---|

Cost-effectiveness | Costs less | May need more buildings |

Recovery rates | Gets more coal | Tunnel size limits how much coal is taken |

Safety | Safer for workers | More dangerous |

Scalability | Pit can grow easily | Harder to change |

Use of heavy machinery | Uses bigger, better machines | Uses smaller machines |

Strip mining is another way to mine coal from the surface. Workers remove strips of soil and rock to get to the coal. They use draglines, loaders, and trucks. Strip mining gets a lot of coal fast. In 2015, each worker mined 11 tons of coal every hour. This method covers large areas quickly.

Mountaintop removal is a special way to mine coal. Workers use explosives and coal mining equipment to take off the top of a mountain. This shows the coal seams below. Mountaintop removal is not as good as strip mining, but it is better than underground mining. This method can hurt the environment. By 2012, it destroyed 1.4 million acres of forest in Appalachia. Fish numbers dropped by two-thirds near mining sites. The Cerulean warbler bird lost almost 70% of its population since 1966.

"If any living thing cannot live in a pile of rocks, it is gone. No other effect on the environment is worse than this." — U.S. District Judge Charles H. Haden II

When using surface mining, safety and the environment are important. There are risks like air and water pollution, land damage, and health problems for people nearby. Workers must use modern coal mining equipment and follow safety rules to keep everyone and nature safe.

Underground coal mining helps workers reach coal deep underground. This process is used when coal is too far down for surface mining. Workers enter mines through shafts or slopes. Shafts go straight down, and slopes are slanted tunnels. Workers use advanced equipment and follow strict safety rules to stay safe.

About 60% of the world’s coal comes from underground mining. There are two main types: room-and-pillar and longwall mining. Some places use shortwall and thick-seam methods too. Each method uses different equipment and safety systems to help workers and make mining better.

In room-and-pillar mining, workers use machines called continuous miners. These miners cut out rooms in the coal seam. Pillars of coal are left to hold up the roof. Equipment like shuttle cars, roof bolters, and ventilation systems are used. Workers enter through shafts or slopes and make rooms and pillars in a grid pattern.

This method has many good points:

Advantage | Description |

|---|---|

Safety and stability | Pillars keep rooms safe and stop cave-ins. |

Cost-Effective | This method saves money and helps recover costs fast. |

Adaptable | It works in many rock types and stays effective. |

Eco-friendly | Less rock is removed, so nature is less harmed. |

Workers wear helmets, respirators, and other safety gear. They follow safety rules like checking roofs and watching air quality. CCTEG Xi'an Research Institute gives smart drilling rigs and monitoring systems. These tools help workers see conditions right away. Technology makes mining safer and more dependable.

Longwall mining uses machines to cut big panels of coal. Workers set up a long wall of coal, sometimes very long. Hydraulic shields hold up the roof while coal is cut. The shields move forward as mining goes on, letting the roof fall safely behind.

This method gets lots of coal:

Longwall mining gets about 80% of the coal.

The average recovery rate is 79.6%.

The best results happen with thick seams and good equipment.

Over 44,000 metric tons of coal can be mined each month.

Workers use shearers, armored face conveyors, and roof supports. Safety systems and gear help protect everyone. Smart sensors and real-time monitoring from CCTEG track gas, roof movement, and equipment. Technology helps workers act fast if there is danger and keeps mining safe.

Shortwall mining uses continuous miners and smaller panels than longwall mining. Workers use backfill to hold up the roof and control movement. This method works well in thick seams where extra support is needed.

Workers follow safety steps:

Backfill controls roof movement and keeps workers safe.

Using backfill helps the environment.

Pillar width and mining height are chosen for stability.

Full caving helps get more coal and improves safety.

Backfilling without pillars saves money and makes energy storage.

Workers use continuous miners, roof bolters, and shuttle cars. They wear safety gear and follow safety rules. CCTEG’s smart monitoring systems give real-time data on water and gas. Technology helps workers avoid danger and makes mining better.

Underground coal mining uses new technology to keep workers safe and productive. Continuous miners, automated longwall systems, and smart tools help every step of mining.

Technology has changed underground coal mining. Automation, digitization, and smart sensors help keep workers safe. Here is a table of some big improvements:

Technological Advancement | Impact on Safety |

|---|---|

Automation | Cuts down mistakes and makes work safer. |

Digitization | Makes data better and helps monitor in real time. |

Smart Sensors | Tracks conditions and worker safety better. |

Autonomous Machinery | Lowers risks from human-operated machines. |

Communication Systems | Helps workers talk during emergencies. |

Real-time Monitoring | Lets workers respond fast to danger. |

Drones | Checks sites without risking lives. |

Rock Bolting Technology | Stops rocks from falling in mines. |

Antioxidants | Controls coal fires that start by themselves. |

Workers depend on safety gear, safety systems, and strict rules to stay safe. CCTEG Xi'an Research Institute makes smart mining equipment and monitoring systems. These tools help workers mine safely, work faster, and protect nature. Underground coal mining keeps changing, making mining safer and better for everyone.

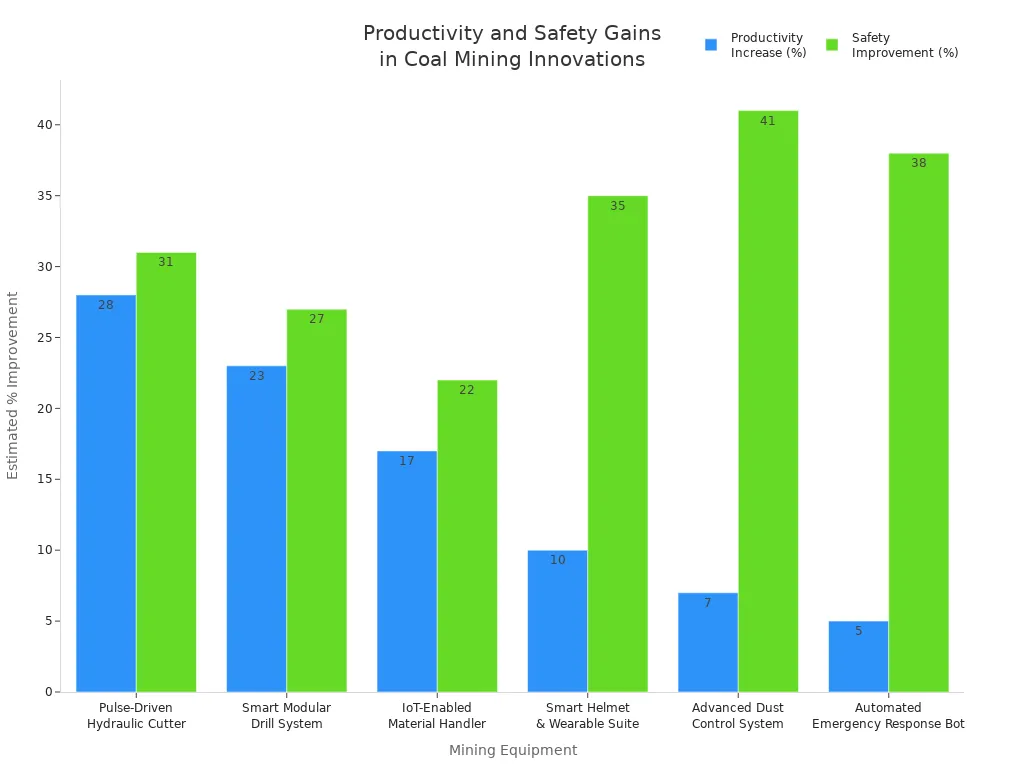

Coal mining is changing because of new smart machines. CCTEG Xi'an Research Institute makes tools like the YCSZ drilling instrument and KJ117(A) monitoring system. These tools let workers watch things in real time and make safer choices. Workers can use smart helmets, automatic cutters, and IoT machines to stay safe and work faster. The table below lists some new tools and how they help mining.

Tool Name | Function/Feature | Estimated Productivity Increase (%) | Estimated Safety Improvement (%) | Sustainability Impact | Estimated Cost (USD) |

|---|---|---|---|---|---|

Pulse-Driven Hydraulic Cutter | Automated, high-precision seam cutting & fragmentation with AI guidance | 28 | 31 | High | 130,000 |

Smart Modular Drill System | Switchable bits, condition sensing, remote operation | 23 | 27 | Medium | 85,000 |

IoT-Enabled Material Handler | Automated loading/unloading, dust suppression, real-time data | 17 | 22 | High | 48,000 |

Smart Helmet & Wearable Suite | Vital monitoring, gas detection, communication, emergency beacon | 10 | 35 | High | 2,600 |

Advanced Dust Control System | Real-time air filtration, smart air flow routing | 7 | 41 | High | 11,400 |

Automated Emergency Response Bot | Hazard detection, evacuation, and rescue support | 5 | 38 | Medium | 59,000 |

These new tools help workers see problems right away. They also help protect the environment and make mining last longer. Automation and data help save energy and lower risks. These changes help mining be safer and better for nature.

New mining technology helps protect the environment. CCTEG’s systems help control water, air, and waste. The DESALX® process cleans water so no dirty water is released. Workers can reuse waste, use green energy, and capture carbon to lower pollution. These new ways help recycle water and stop pollution.

Technology | Description | Benefits |

|---|---|---|

DESALX® | A treatment process ensuring no liquid effluent is discharged. | High recovery of water and salts, applicable to various wastewaters, reduces environmental contamination. |

Water recycling keeps waste out of rivers and lakes. These new ideas help lower harm to nature. Workers can use battery trucks and trolley trucks to cut pollution. Automation and real-time checks make mining safer and better for the planet.

Coal mining will use more robots, AI, and automation soon. These tools will help workers stay safe and work faster. Robots can help get more coal and fix things for less money. New green technology could cut CO2 by half by 2050. AI, better grinding, and heat recovery will help reach green goals.

Disaster plans will get better too. New systems help share news fast and help in emergencies. Local leaders now help pay for emergencies and watch mines more closely. Workers can join rescue teams to keep everyone safe. These new ideas in safety and green mining will change coal mining. Workers will help make mining safer and better for the earth.

Safety is the most important thing in coal mining. Surface mining is usually safer for workers. Underground mining has more dangers, like gas leaks and roof falls. The table below shows the safety risks for each method:

Mining Method | Safety Risks |

|---|---|

Underground Mining | More injuries, harder work, gas leaks, fires, and sudden bursts. |

Surface Mining | Fewer injuries and easier work than underground mining. |

Surface mining gives workers a safer place to work. Underground mining needs better safety systems and more training. New technology, like real-time monitoring, helps keep workers safe in both methods. Workers must always follow safety rules and wear protective gear. Training and smart machines help lower accidents. Safety is always the main goal in every mine.

Surface mining costs less than underground mining. Surface mines need fewer workers and use bigger machines. In places like Wyoming, thick coal beds near the surface make mining even cheaper. Underground mining costs more because it needs more workers and special tools.

How much coal you get depends on the method:

Aspect | Underground Mining | Surface Mining |

|---|---|---|

Productivity | 500 to 800 tonnes/day | 5,000 to 100,000 tonnes/day |

Cost | Expensive but works well | Cheaper way to mine |

Complexity | More dangerous and harder | Easier to reach coal |

Longwall mining gets more coal than room-and-pillar mining. Room-and-pillar leaves some coal behind to hold up the roof. Sometimes, longwall mining is used after room-and-pillar to get extra coal.

Mining can hurt the environment in many ways. It uses lots of water and changes the land. Mining can cause dust and dirty water. Old mines can harm rivers and soil for a long time. Mining can also put metals and chemicals into nature.

Note: Mining companies must follow strict rules to protect the environment. Laws say you must manage waste, stop pollution, and fix the land after mining. If you break these rules, you can get fined and lose trust from people nearby.

You can help nature by using new technology, recycling water, and fixing the land. These steps make mining safer and cleaner for everyone.

You now know about modern coal-mining methods. These include surface mining and underground mining. Today, work is safer because smart technology helps lower risks. Fewer miners are needed because of machines. Sustainable steps, like fixing land and cleaning water, help nature. Companies like CCTEG are leading in these ways:

They turn waste into useful things with special recovery tools.

They use bio-leaching and machines that save energy.

They work with other countries to build a circular economy.

Coal mining will keep getting better with new ideas. It will also become safer and better for the environment.

You will find surface mining safer than underground mining. Surface mining uses big machines above ground. This method lowers the risk of cave-ins and gas leaks. New technology and safety rules help keep you and other workers safe.

You use smart machines and sensors to watch for danger. Real-time data helps you spot problems fast. Automation lets you do more work with fewer mistakes. These tools help you stay safe and work faster.

You can help nature by using new green technology. Water recycling, land restoration, and dust control lower harm. Companies like CCTEG use special tools to clean water and fix land after mining.

You need drills, loaders, trucks, and smart sensors. Underground mining uses roof supports and gas monitors. Surface mining uses draglines and dozers. Smart helmets and monitoring systems help you stay safe every day.